深圳市特普科电子设备有限公司

联系方式:158 1155 1336 (张)

邮 箱:zyzhang@topsmt.com

地 址:深圳市宝安区福海街道塘尾社区荔园路142号翰宇湾区创新港4号楼二层

Siplace MultiStar (CPP) 是同时支持收集和放置模式和拾取和放置模式的贴装头,同时能够在混合模式下运行,将这两种模式结合在一个贴装周期中。

那么,收集&放置模式、拾取&放置模式和混合模式到底是什么?

Siplace MultiStar (CPP) 的收集贴装模式采用元件相机类型 30(高分辨率相机),专为标准元件的高速贴装而设计,尺寸范围为 01005 mm 至 27 mm x 27 mm。

在此模式下,Siplace MultiStar 在旋转的同时收集元件,其中每个吸嘴都可用于收集小元件:位于更低位置的吸嘴首先收集小元件,然后 CPP 贴装头会快速旋转以放置下一个可用的吸嘴到更低位置的前一个喷嘴,然后这个现在更低位置的喷嘴收集另一个小成分。这个过程可以重复,直到所有 12 个喷嘴都收集到元件并继续放置它们。元件贴装过程与收集过程类似,CPP贴装头一边旋转下一个吸嘴至合适的贴装角度一边进行贴装,因此也可以将小元件紧密贴合放置。

以下是 Siplace MultiStar 在收集和放置模式下的图形演示:

拾取&放置模式

Siplace MultiStar (CPP)的拾取和放置模式采用33型组件相机(固定小间距相机),专为放置大型或特殊组件而设计,其尺寸范围从0402到50mm x 40mm(多次测量期间也可以使用69 mm的对角线(例如60 mm x 10 mm))或某些要求只能通过放置在小间距领域来满足。

在这种模式下,CPP放置头直接向下捡起一个大部件,向上移动到上面的目标放置位置,然后按照所需的放置角度向下放置组件,而CPP放置头上的一些喷嘴由于大部件占用的空间大而无法使用。在整个拾取和放置过程中,只有当Siplace MultiStar调整到合适的放置角度时才会发生旋转。

下面是Siplace MultiStar在Pick & Place模式下的图形演示:

混合模式

Siplace MultiStar的混合模式采用30型组件相机(高分辨率相机),设计用于放置各种类型的组件,其尺寸范围从0402到50mm x 40mm(多次测量时也可以使用69 mm的对角线(例如60mm x 10mm))。

在这种模式下,Siplace MultiStar可以在收集和放置模式和拾取和放置模式的组合中运行,这意味着CPP放置头可以收集或拾取组件,旋转,然后继续收集或拾取另一个组件,并且可以在放置时以类似的方式收集或选择。当组件的大小不够小时,会有未使用的喷嘴,就像在拾取和放置模式中一样,为它腾出空间。如果组件太大、太重或需要特别小心,Siplace MultiStar的旋转将受到限制。

下面是Siplace MultiStar在混合模式下的图形演示:

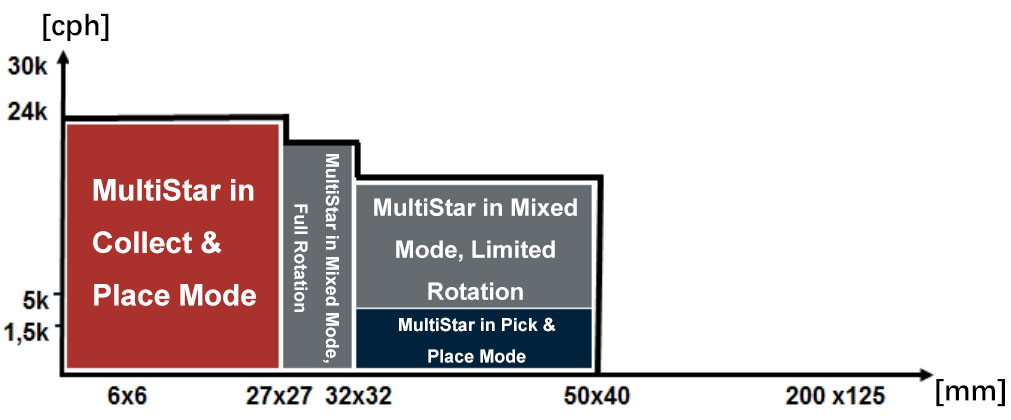

应该采用哪种安置模式?

下面是Siplace MultiStar放置模式选择的图解结论:

158-1155-1336

联系人:张小姐

邮 箱:zyzhang@topsmt.com

地 址:深圳市宝安区福海街道塘尾社区荔园路142号翰宇湾区创新港4号楼二层